Need to connect an aluminum cable quickly and securely? With the new UBAL terminal series from Phoenix Contact, you can meet this challenge.

The operation of an aluminum cable differs from a copper cable in the following factors:

The electrical resistance of aluminum is higher than copper, so the cross section of the aluminum cable must be chosen one step larger at the same load level.

When aluminum and copper cables come into contact and in the presence of moisture, electrochemical corrosion is formed.

Aluminum oxidizes much faster than copper. The aluminum oxide film is very dense and does not conduct current, so you need to process the cable before connecting.

Aluminum is softer than copper, so the screw terminal with aluminum cable must not be tightened "to the stop".

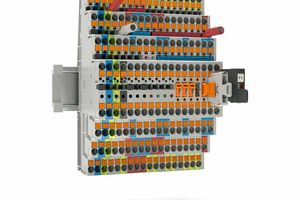

Phoenix Contact offers a solution to all these challenges with the brand new UBAL series of screw terminals, which are designed to take into account all the features of aluminum conductors and allow you to ensure reliable contact and reduce the time for preparing the aluminum cable.

Choosing new terminals of the UBAL series, you get:

A series of terminals for aluminum cables from 6 mm2 to 240 mm2.

The terminals are equipped with protective paste against oxidation of aluminum cables.

Possibility of connecting copper and aluminum cables from different sides of one terminal, because connection zones are separated by an insulating partition.

Sturdy flame retardant plastic housing.

6 body color options.

UBAL series terminals can be used in projects where there is a high risk of misuse of expensive copper cable, as well as to reduce the weight of cable lines.

More about UBAL series terminals